Electroplating Activated Carbon

Description

Electroplating Activated Carbon

Electroplating activated carbon is made from wood or coconut shell as raw materials (some manufacturers with low requirements for electroplating processes also use coal based activated carbon).

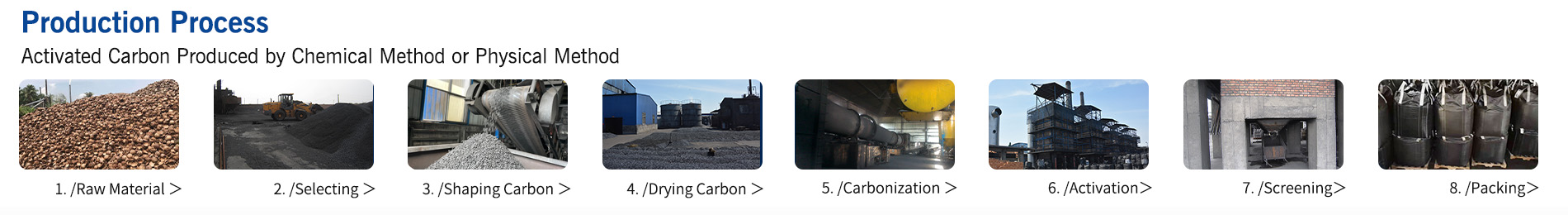

This product is refined through processes such as crushing, acid washing, rinsing, drying, temperature controlled carbonization, and temperature controlled activation. There are two types particles and powdered, which have the advantages of large specific surface area, strong adsorption capacity, high mechanical strength, multiple oxygen-containing genes on the surface, and strong positivity.

It is mainly used for metal finishing such as nickel plating, hydrogen copper plating, silver plating, copper tin alloy, HEDP copper plating, and electroplating. Due to its efficient adsorption capacity, the coating is non brittle and prevents the occurrence of bottom layer flower phenomenon. The activated carbon is also suitable for removing impurities from electroplating solutions in electroplating factories and adsorbing heavy metals such as copper and silver in electroplating wastewater. It has significant effects on purifying and removing impurities from electroplating solutions, and is one of the important means to improve the quality of plated products. It can make the coating uniform, crystal fine, porosity small, and firmly bonded.

Characteristics:

Electroplated activated carbon has the characteristics of high fineness, large specific surface area, strong adsorption capacity, abundant oxygen-containing genes on the surface, well-developed molecular structure micropores, and high reactivity.

Electroplating principle:

Electroplating refers to the process of electrolytic reaction in a solution using external direct current to deposit a metal or alloy layer on the surface of a conductive material such as metal. The copper sulfate plating solution mainly includes copper sulfate, sulfuric acid, and water, and even other additives. Copper sulfate is the source of copper ions (Cu2+). When dissolved in water, copper ions will dissociate and deposit into metallic copper at the cathode (workpiece) through reduction (obtaining electrons). This sedimentation process is affected by the conditions of the plating bath, such as copper ion concentration, pH, temperature, stirring, current, additives, etc.

Index/ Type | Electroplating activated carbon | Electroplating granular activated carbon | Electroplating wastewater activated carbon |

Size | 200-325 mesh | 40-80 mesh | 200-325 mesh |

Moisture | ≤5 % | ≤5 % | ≤10 % |

Ash | ≤3 % | ≤5 % | ≤12 % |

Methylene blue mg/g | 105-210 mg/g | 105-180 mg/g | 105-180 mg/g |

PH | 5.5-7.5 | 5.5-7.5 | 7-9 |

Chloride | 0.02 % | 0.02 % | 0.1 % |

Sulfate | 0.1 % | 0.1 % | / |

Acid soluble substances | 0.8 % | / | / |

Soluble ash content | Negative in HEDP plating solution | Negative in HEDP plating solution | / |

Remarks: The specification can be customized according to customers’ requirement.

Production & shipment

Henan Shangchen New Material Technology Co., Ltd. has over 30 years history in producing and selling activated carbon.The company can provide specifications and solutions customized services with advanced workshops and equipment.The company will continue to be committed to technological innovation and product quality, and provide customers with better quality activated carbon products and services.