Air Purification Activated Carbon

Description

Air purification activated carbon uses the materials with higher carbon as raw material such as coal, nut shell, coconut shell,wood and etc. The product is produced through professional activating treatment to form abundant micropore, which makes the specific surface area and adsorption capacity achieve certain requirements. The activated carbon production usually divides into two processes, one is carbonization, the other is activation. Activated carbon includes decolorization activated carbon, water purification activated carbon, air purification activated carbon, heavy metal recovery activated carbon and so on. It has widely usages, and is the high quality adsorbing material.

Air purification activated carbon is one kind of activated carbon, and specially used for purification of polluted air. The activated carbon for air purification must have the characteristics of good hardness, high strength, micropore structure. The nut shell carbon, coal carbon can be used as the raw materials of air purification. The nut shell carbon has the best effect.

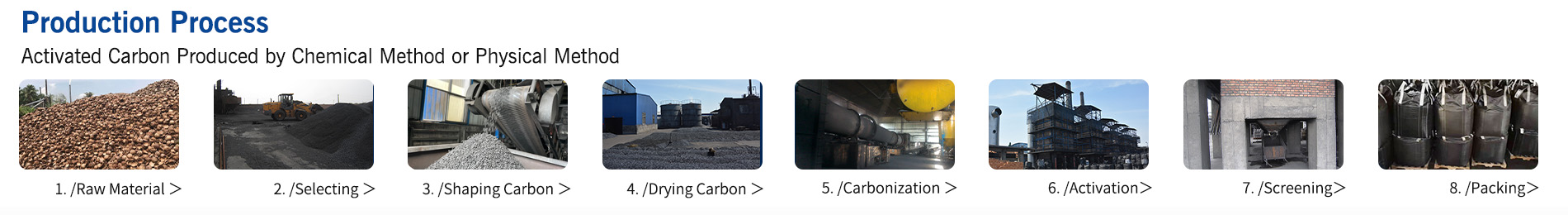

The process of activated carbon production

1. Carbonization

The nut shell carbonization furnace is used to through pre-heat, then go into the carbonized process with high temperature heating from 450 to 500, and provide air combustion-support without any other fuel. Then the process goes into cooling coil section. The carbonized exhaust won’t pollute the air. The structure of the carbon is graphite shape hexagonal microcrystalline.

2. Activation

The activation of activated carbon uses air activation method. Usually the activated carbon activation furnace uses the steam and the activation process produced flue-gas as activator to finish the activation process together. The activation needs the high temperature from 850 to 950, about also needs 10 atmospheric pressure.

Activated carbon adsorption effect principle

Air purification activated carbon is black and one kind of microcrystalline carbon materials with advanced internal pore structure, large specific surface area and strong air adsorption ability. The material has a plenty of invisible micropore, the specific surface area of micropore of 1g activated carbon material unfold can achieve 800—3000 square meter, and the specially usage activated carbon can achieve higher. It means that the internal surface area of micropore of a rice grain-size air purification activated carbon particle may equivalent to a sitting room area. Because of the highly development and just as human blood capillary pore structure, the activated carbon owns excellent adsorption capacity.

Features

- Selected raw materials

- High surface area/Developed pore structure

- Good adsorption capacity for many pollutants

- High hardness and wear resistance

- Low ash content and low density

Items | Test data | Items | Test data |

Iodine Value | 600-1100 mg/g | Packing density | 0.45-0.55 g/cm3 |

Specific surface area | 700-1100 m2/g | Ash | 8-12 % |

Strength | ≥95 % | Moisture | ≤5 % |

pH | 8-11 | CTC | 40-70% |

Remarks: The specification can be customized according to customers’ requirement.

Production & shipment

Henan Shangchen New Material Technology Co., Ltd. has over 30 years history in producing and selling activated carbon.The company can provide specifications and solutions customized services with advanced workshops and equipment.The company will continue to be committed to technological innovation and product quality, and provide customers with better quality activated carbon products and services.