Catalyst Carrier Coconut Shell Activated Carbon

Description

Catalyst Carrier Coconut Shell Activated Carbon Product Introduction

Catalyst carrier activated carbon is on the basis of coconut shell activated carbon, with the iodine above 900 mg/g. The activated carbon iodine can achieve above 1150 mg/g after modified.

Catalytic is a kind of very small carbon grains, and has large surface area, and smaller pore as capillary in the carbon granule. This capillary has very strong adsorption ability, can fully touch with gas or impurity for the large surface area. When the gas or impurity touch the capillary will be adsorbed to play purification effect. It is widely used as the catalyst carrier in the industries of high purity gases, liquid, petrifaction, also can be used for desulfuration, deodorization in petrochemical industry.

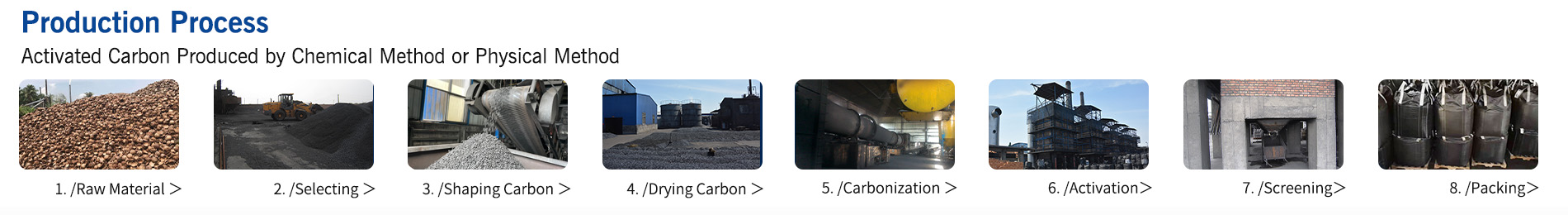

1) Production method

① Steam, gas activation method. Use steam or carbon dioxide to make the carbon activate in 850—900 degrees Celsius.

② Chemical activation method. Use the activator released gases or activator dipped raw materials, both of which can get activation after high temperature processing.

③Superheated steam, ammonia, air are heated together to a high temperature to make the carbon matrix to be activated, or after non-carbonized materials are dipped in zinc chloride, ammonium chloride, calcium chloride, sulfuric acid to be activated in low temperature, then the activated carbon is produced by firing and activation. Purification carbon needs to be processed by acid or alkali treatment after activation.

2) Catalyst features

Activated carbon has microcrystalline structure, Microcrystalline arrange fully irregular, Crystals have micropores, medium pores, large pores, so they have large internal surface area, the specific surface area is 500—1700㎡/g. The surface make the activated carbon has good adsorption, can adsorb metal ion, harmful gas, organic pollutant, pigment in the wastewater and waste gases. Activated carbon used in industry demands high mechanical strength, good abrasion resistance, its structure strives to stable and adsorption needs a little energy, which conducive to renewable. Activated carbon is used for decolorization, deodorization, gas separation, solvent recovery and air conditioning of oil, beverage, foodstuff, drinking water, and also used as catalyst carrier and the adsorbent of gas mask.

Physical and chemical properties analysis

| Items | Test data | ||||

| Granularity(mesh) | 4-8、6-12、8-30、12-24、20-40、30-60、40-80 | ||||

| Iodine value(mg/g) | ≥700 | ≥800 | ≥900 | ≥1000 | ≥1100 |

| Specific surface are(m²/g) | ≥750 | ≥850 | ≥950 | ≥1000 | ≥1100 |

| PH | 8-11 | 8-11 | 8-11 | 8-11 | 8-11 |

| Strength(%) | ≥96 | ≥96 | ≥95 | ≥95 | ≥95 |

| Moisture(%) | ≤10 | ≤10 | ≤5 | ≤5 | ≤5 |

| Ash(%) | ≤5 | ≤5 | ≤3 | ≤3 | ≤3 |

| Loading density(g/L) | 500-550 | 500-550 | 450-550 | 450-550 | 450-550 |

Remarks: Product specification can be customized according to customers’ requirements.

Production & shipment

Henan Shangchen New Material Technology Co., Ltd. has over 30 years history in producing and selling activated carbon.The company can provide specifications and solutions customized services with advanced workshops and equipment.The company will continue to be committed to technological innovation and product quality, and provide customers with better quality activated carbon products and services.